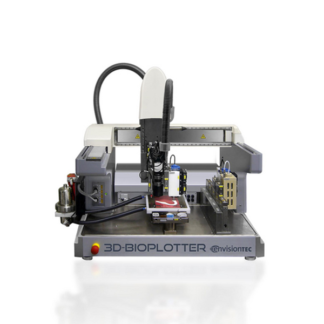

Description

Technical Specifications

Layer Resolution: to 50 microns

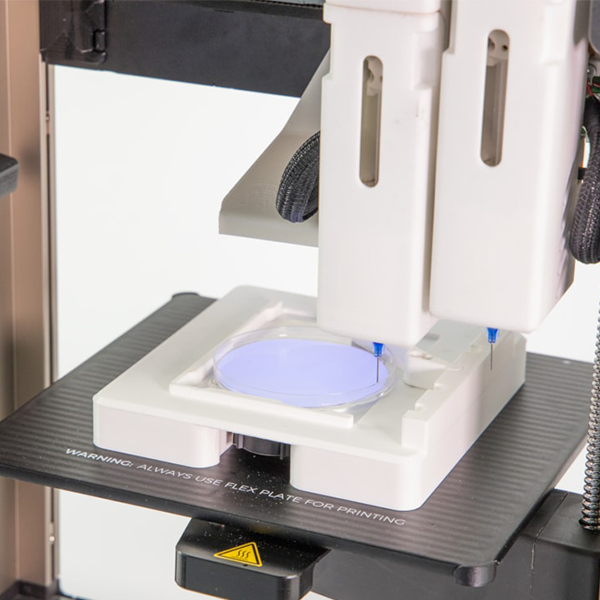

Build Plate: Aluminium sandwich plate with steel flexplate.

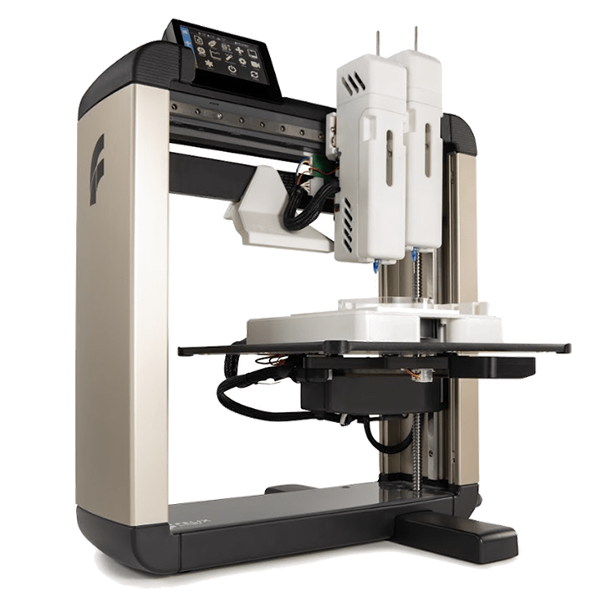

Print head: Dual syringe operation

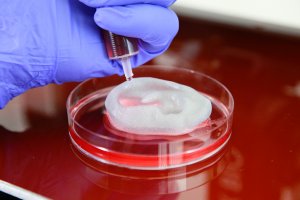

Syringe Specs: 5 ml syringe(s)

Build Speed/s: Recommended build speed is 20 mm/s. Speed depends on material viscosity.

Typical print accuracy: ± 0.05 mm for sizes below 20 mm

Syringe Min/Max print temperatures: 0-50 ˚C

Syringe heat up time / cooling times: 10 seconds

XYZ resolution: XY, 1.6 microns, Z: 0.15 micron

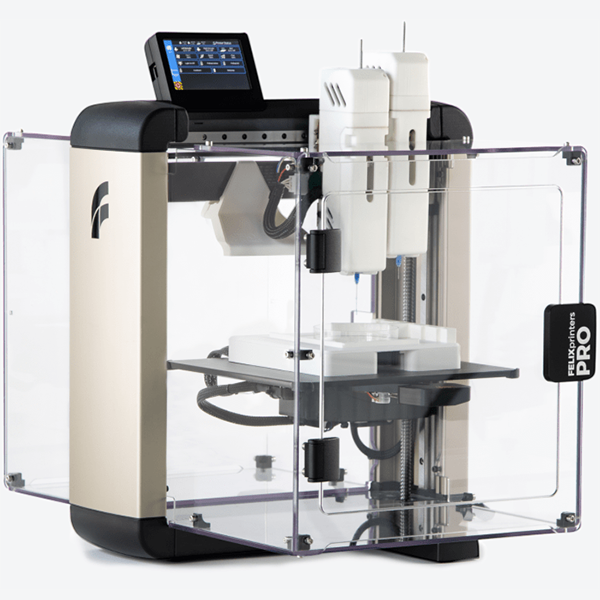

Dimensions & Weight: 430 x 390 x 550 mm, 11.5kg

Build Volume: XYZ = 130 x 210 x 130 mm

Extrusion width: greater than 0.1mm, depending on nozzle size

Extrusion resolution: 0.000180 ml per step