Description

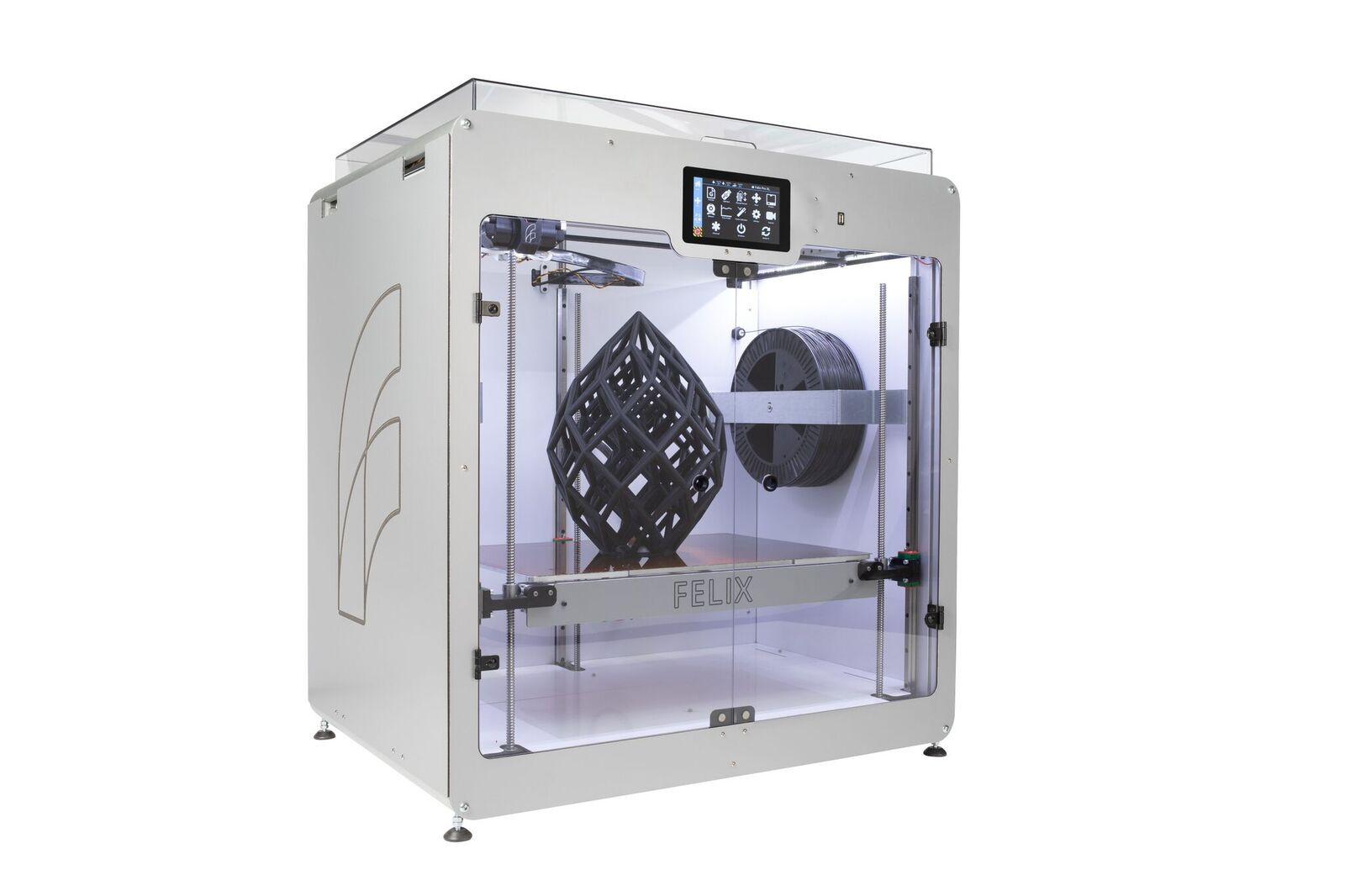

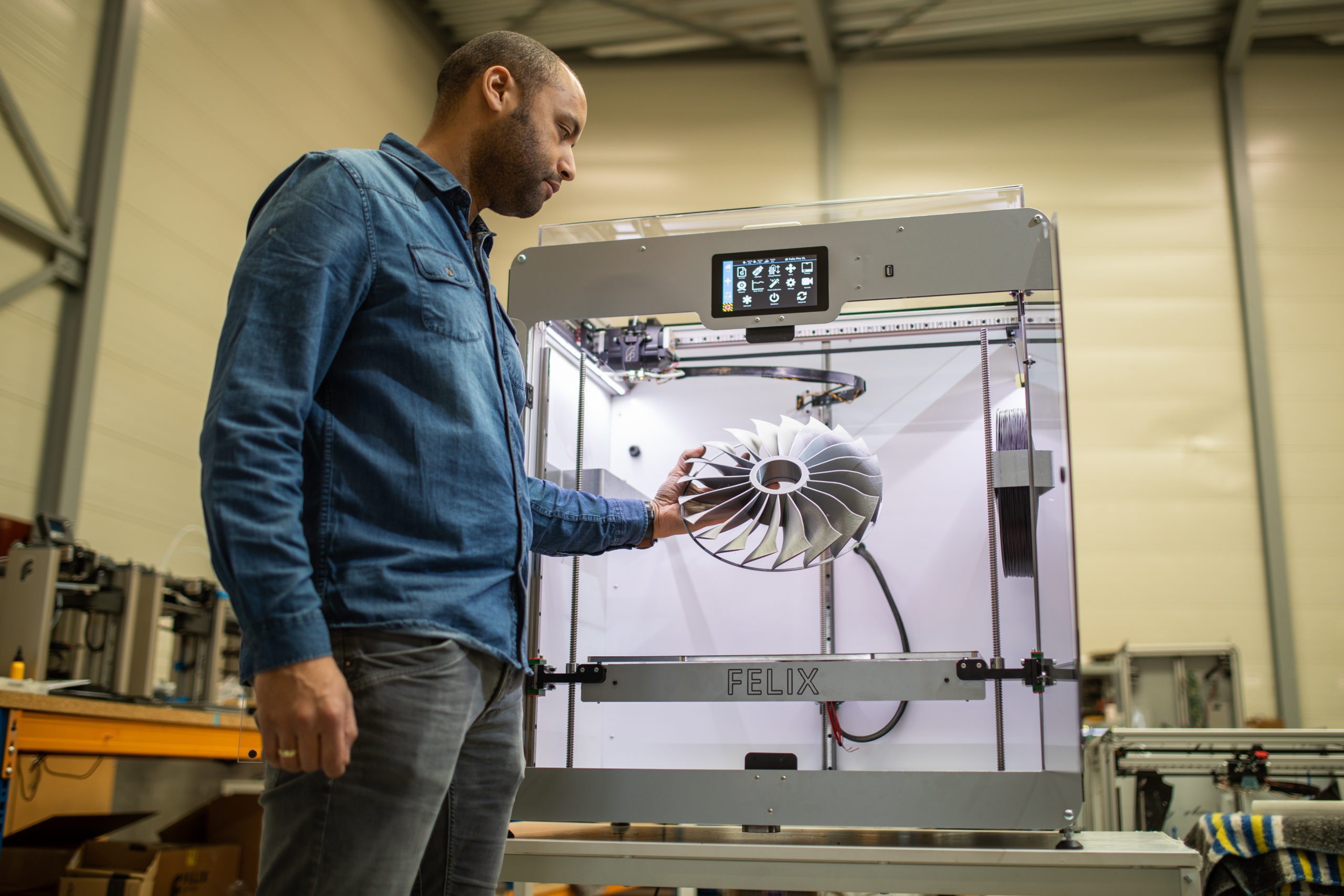

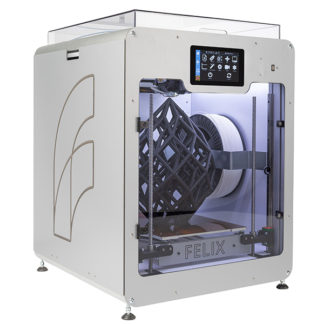

FELIX Pro XL

A big printer that can fit through your door.

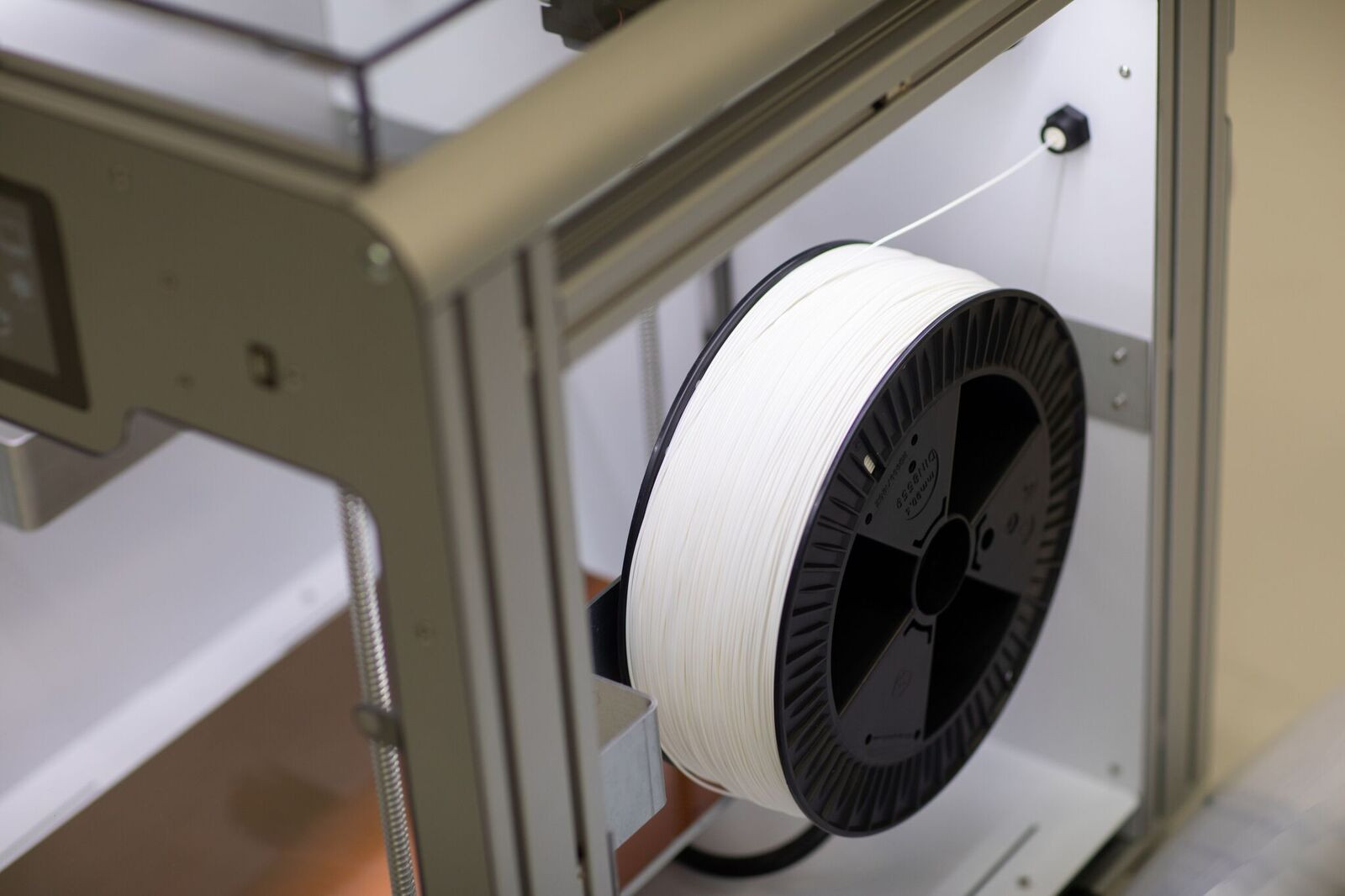

The Pro XL can work with a wide selection of filament, including PLA, ABS, PETG, PVA, FLEX, Carbon fiber, Nylon, Glass and Wood ll.

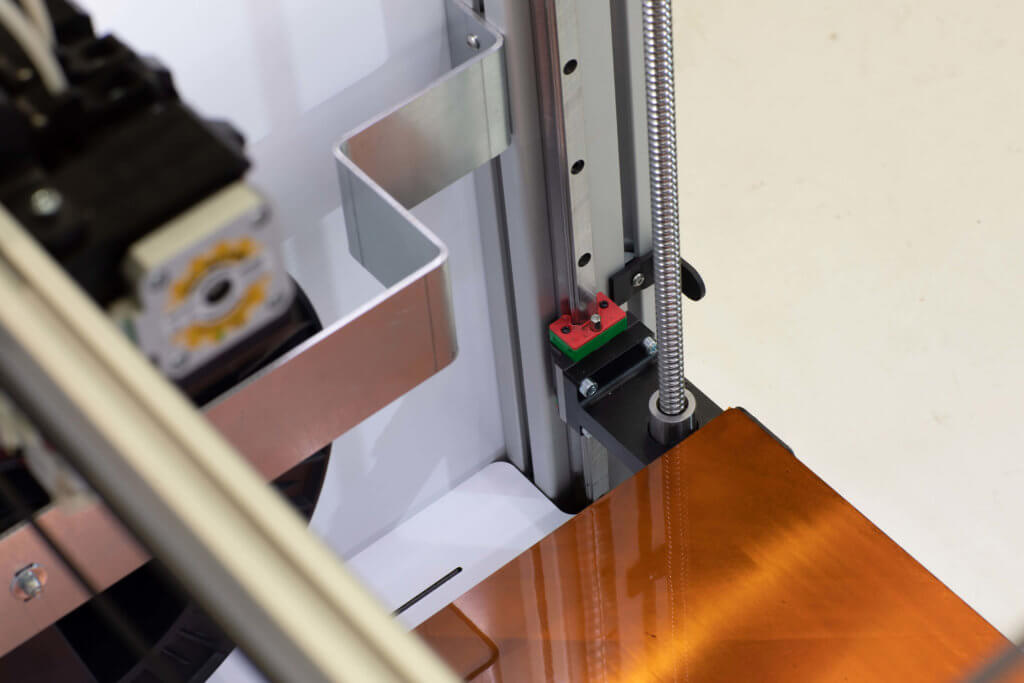

To ensure the quality and reliability upon which FELIX printers has built its reputation, this system incorporate highly engineered print chambers, which incorporate an enclosed warm zone and a cold zone. The warm zone supports consistent temperature control during the build, which is particularly important when printing materials with a high shrinkage factor, such as ABS, carbon fiber or Nylon. The cool zone houses the printer’s electronics, making sure that they don’t overheat and cause problems.

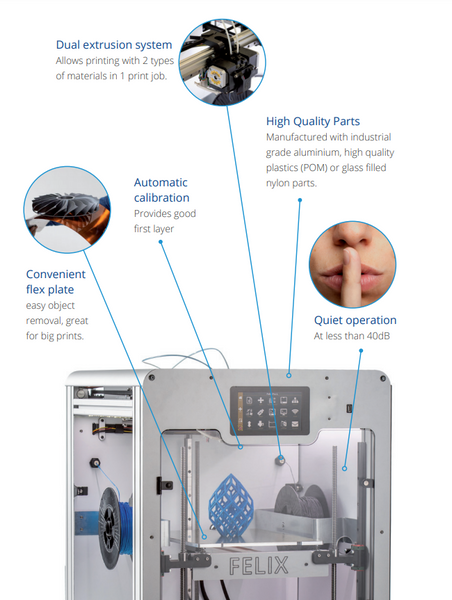

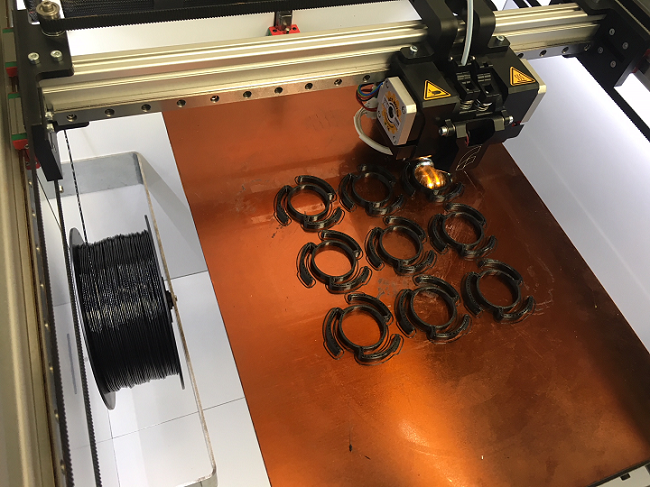

The Felix Pro XL integrates dual extrusion printing and a special mechanism that ensures the print heads operate symbiotically. That is, when the dual nozzles are printing they remain at different print levels, eliminating any risk of collision and reducing the chances of print failure. Further, if only one nozzle is in use, the other will automatically rotate away from the print, so that there is no interference.

Other features, such as an intuitive 18 cm touchscreen module with integrated print-server allow for unparalleled ease of use. This particular feature, consisting of a “small but powerful” octacore computer, enables users to remotely monitor their prints via webcam, manage print files, render G-codes and even create a time lapse of the print. In terms of connectivity, the large-format 3D printers can be accessed by USB and/or WiFi, and can be connected in a LAN network or as a standalone machine.

While very large, the Pro XL formfactor has been designed specifically to be easily movable — at installation or within a manufacturing setting it can easily be transported through a normal office door opening (900 mm).

Base Specifications

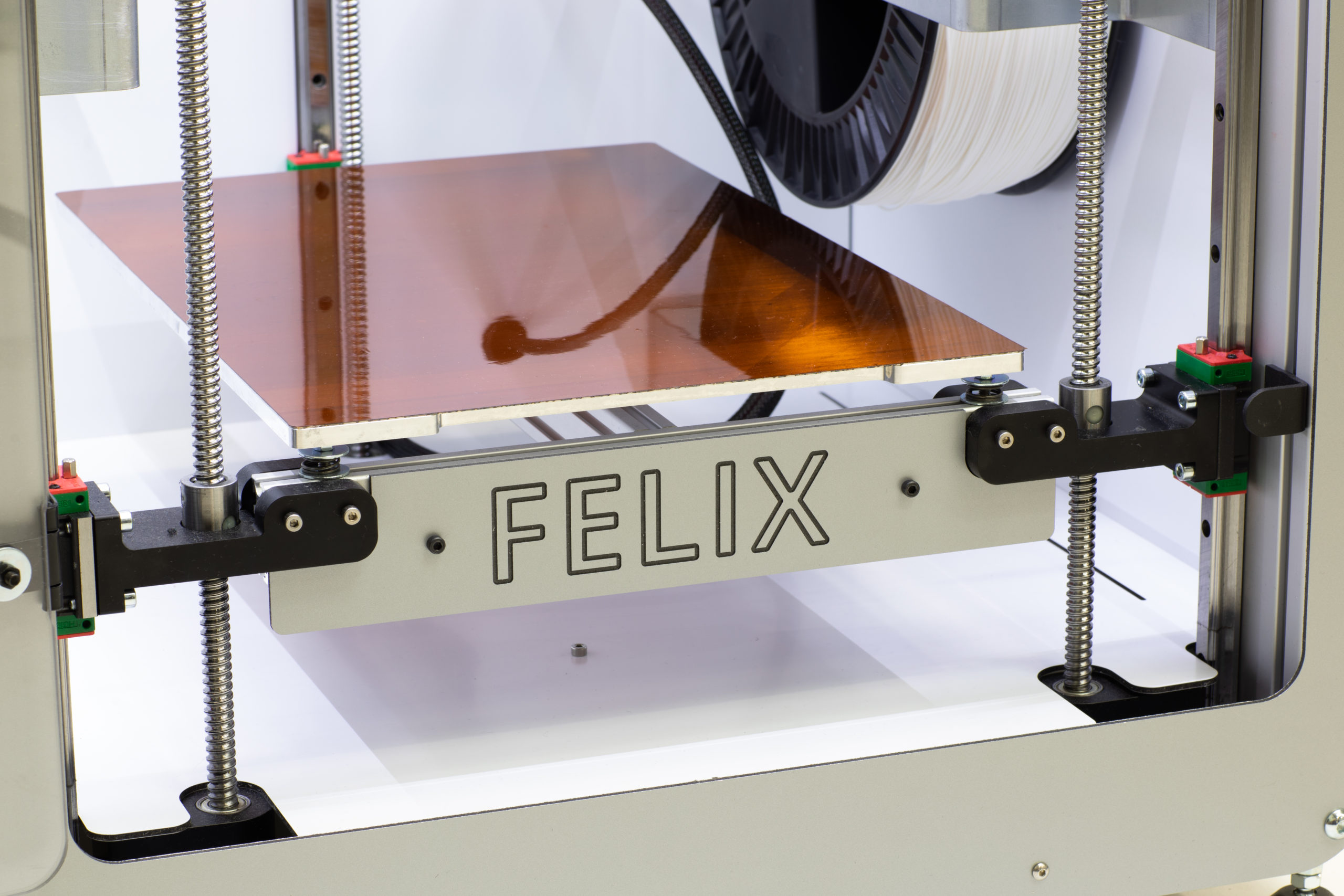

- Build size (LxWxH): 600 x 400 x 600 mm or 23.62″ x 15.75″ x 23.62″

- Build volume: 144 Liter / 42 Gallon

- Physical dimensions (LxWxH): 906 x 666 x 966 mm or 37” x 26” x 38”

- Total weight: approx. 80 kg