3D printing in the medical industry takes many forms. When it comes to its use in brain science, 3D printing is quickly becoming a-go-to option in the field. These tools provide scientists, practitioners, and researchers with novel methods to better understand and tackle the complexities of the brain. As a result, 3DP helps to advance the approach and treatment of various brain injuries and disorders. While at the same time helping to build new paths and insights in cranial and neuroscience research.

Below we’ve summarized two common ways that easily accessible 3DP tools have already helped providers and patients. In addition, we’ve touched on one recent breakthrough that hints at the future of additive in such fields as bioengineering. We think that these are fascinating examples!

Image courtesy of https://www.renishaw.com/en/digital-evolution-of-cranial-surgery–38602

Anatomical Models

3D printed anatomical brain models help surgeons in both the planning and the practice of surgical procedures. Specifically, these models are meant to accurately replicate patients’ anatomy and they help to customize patient care. The models aid in “preoperative simulation” and they do this by providing tactile visualization. These tools enable practitioners to anticipate challenges and optimize approaches to meet specific surgical goals. Such models have been proven to ultimately enhance surgical outcomes by reducing complications and improving patient safety.

The 3D printing technologies used to produce these models vary widely. From desktop material extrusion (MEX) systems and multicolor MEX systems, to industrial technology full color and multimaterial systems. With MEX, bone structures and fractures are presented as a physical object. And models of cranial plates and surgical guides can be handled like a hands-on puzzle. With multimaterial and full color systems users can simulate complex surgical procedures, organ nesting, and more. Providers can “see” brain tissue placement, structure interactions/blocking, and complex tumor growth all based on real world patient MRIs. It’s not just existing anatomy that can be analyzed physically. Representing missing anatomy as 3D prints allows for a hands on experience in fine tuning the surgical approach for specific goals.

“The average scores showed that the 3D-printed brain tumor model was superior to [MRIs] for surgical planning surgery in all aspects” –

https://www.nature.com/articles/s41598-021-86546-y

That said, the implementation and roll out of such care tools is not always smooth sailing. Basically, as with many healthcare related advancements and patient centric point-of-care tools, there are barriers and roadblocks to wider implementation. Overall, 3D printing in the medical industry still has numerous resource and adoption based hurdles to overcome

“One of the biggest barriers to entry for establishing a point-of-care medical models program is finding and funding the dedicated, trained professionals for segmentation of the DICOM data” – Evan Hochstein, senior healthcare solutions engineer at Stratasys.

https://all3dp.com/1/3d-printed-medical-models/

Image courtesy of https://all3dp.com/1/3d-printed-medical-models/

Cranial Surgery – Plates and Guides

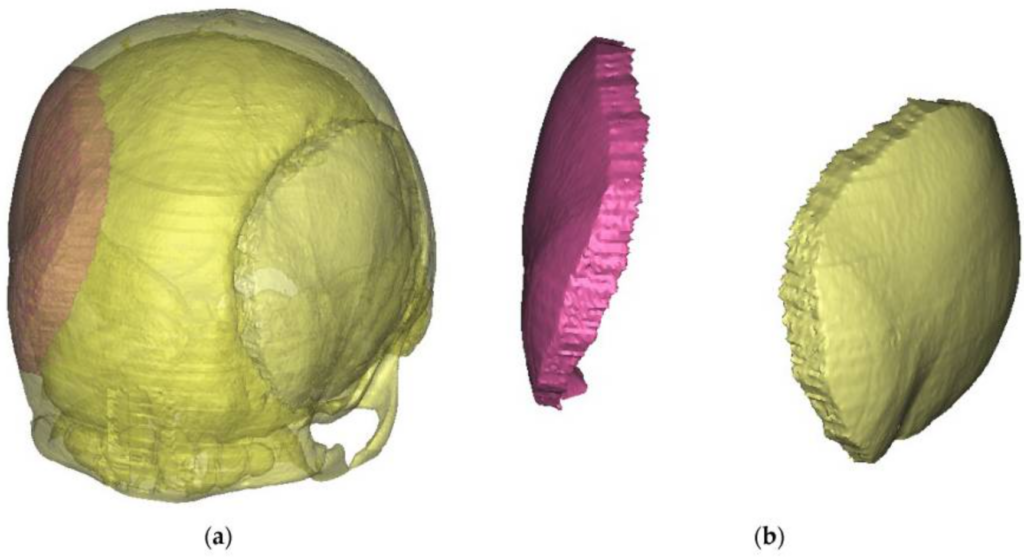

As 3DP normalization occurs, printed titanium or PEEK cranial plates and matching cutting guides see increasing use in patient care. From tumor removal to cranial injury management a growing collection of case studies show the effectiveness of a customized and detailed approach to production and patient care. Well documented benefits abound in 2024. For example, 3D printed plates have a much more exact fit the patient’s skull. Or, precise 3D printed cutting guides help attain critical time improvements in operating theaters. Often removing the need to further form and shape the parts as per traditional manufacturing.

“Using the 3D-printed cutting guide and implant saved us approximately 30 per cent of the time required for this kind of surgery” – Neurosurgeon Bartolomé Oliver, MD, PhD (Spain)

https://www.renishaw.com/en/digital-evolution-of-cranial-surgery–38602

In addition to direct 3D printed plates, MEX processes and digitization techniques help in performing cranioplasty surgeries in resource constrained operating theaters. This is especially of concern in high barrier to access situations and resource constrained environments. For example, lower income countries or healthcare districts / facilities. Accordingly, in these environments the access to cheaply produced MEX or VAT 3DP molds helps to create cost effective PMMA implants based on available patient image data. A fascinating blend of high tech and low tech tools to meet patient needs.

Advances in 3D imaging and printing hold promise for refining craniofacial reconstruction in resource-constrained settings.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10608598/

Image and description courtesy of https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10608598/

The future of 3D printing in the medical industry – 3D Printed Synapsis?

In February 2024 researchers at the University of Wisconsin–Madison shared the development of a novel method to 3D print viable brain tissue. This tissue “can grow and function like typical brain tissue.” As per the press release and study, the main impediment to fully functional connections has been, in part, a lack of oxygen and access to the nutrient rich solution surrounding each neuron. Another issue is that previously used gel mediums are too rigid. In this case, researchers used a more “liquid” (softer) bioink to suspend the matrix horizontally rather than in a tight vertical stack.

“The printed cells reach through the medium to form connections inside each printed layer as well as across layers, forming networks comparable to human brains. “

https://news.wisc.edu/uw-madison-researchers-first-to-3d-print-functional-human-brain-tissue/

Essentially, as the researchers state, they have developed a novel platform for the study of crosslinking and communication between various types of neurons. And now, they will build (pun intended) on this discovery to better understand drug delivery systems, neural degeneration, and diseases such as Alzheimer’s. Other researchers will likely take these findings and explore methods of better oxygen and nutrient delivery through stacked micro structures.

Image courtesy of https://www.cell.com/cell-stem-cell/fulltext/S1934-5909%2823%2900439-3

All images and quotes courtesy of their respective providers and creators and used here for education and editorial purposes only. Relationships are not implied.