Fused Filament Fabrication / Fused Deposition Modeling

FFF / FDM is appropriate for all industries and applications

Fused Filament Fabrication, also known under the trademarked name of FDM (Fused Deposition Modeling) or material extrusion (MEX), is an additive 3D printing process. It usually uses a spool of continuous thermoplastic material for feed stock but can also use pellets. The material is slowly melted and extruded onto a platform layer by layer to create your object.

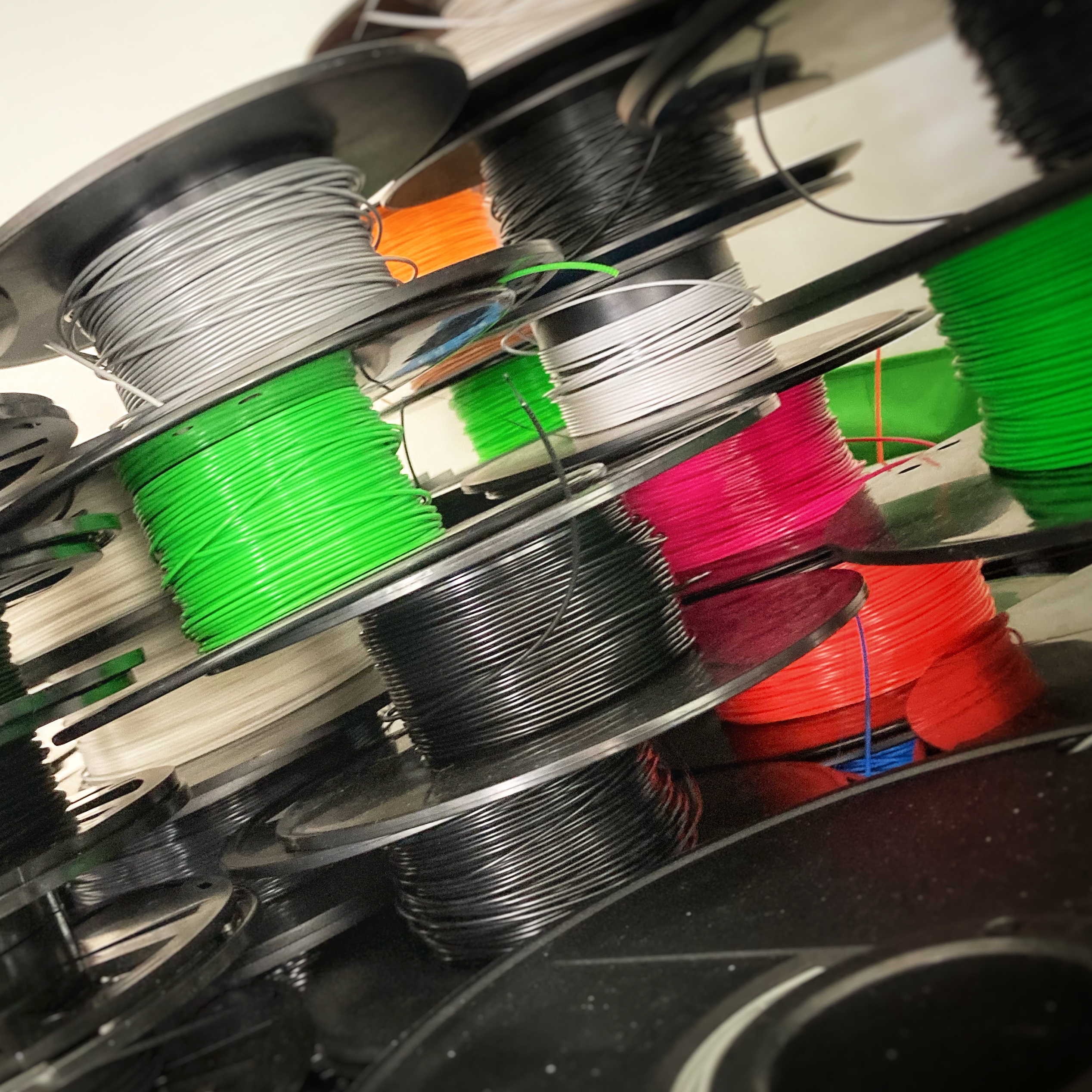

Our service bureau has a wide selection of FDM 3D printers and materials to tackle a wide variety of customer needs on site.

As a Value Added Reseller and with almost 15 years of industry experience we can provide trusted consulting advice on the best printer & technology for your application. From high detail and small scale to large scale component construction or repetitive batch production. FDM materials come in a wide variety of choices and properties – impact resistance, clarity, temperature resistance, embeddable inks, flexibility, UV resistance, affordability, strength and so much more.

Printers and Materials

FFF / FDM

Materials that are routinely in stock are:

- ABS, ASA, PLA, Carbon Fiber, Nylon, PETG, MF ONYX, PCABS, ESD, and TPU

Additional materials and colors can be specialty ordered.

What can we print for you?